Services

JPP is a service-oriented company.With the advantages in technologies, equipment and technician team, JPP can offer clients the following, not limited to, tailored services:

JPP offers our customers more than raw materials.Value-added service would be preferable to our customer and what JPP strives for.

- Cutting

- Beveling

- Coating

- Precise machining

- Heat treatment

- Hot expanding

- Bending

- Slotting

- TPI

JPP’s partnership with qualified mills offer customers easy access to reliable tubular steel products. No matter small quantity, diverse items or short delivery, JPP provide you package service.

JPP knows customer needs and maintains regular inventory ready for dispatch. Work well with land transportation &local freight forwarder, JPP ensures safe, on-time, cost-effective delivery to anywhere needed.

JPP technical support department is the backbone of our quick response and professional analysis to material demands. Management group and supervision team work together to help customers figure out the best tubular solutions.

JPP is capable of flexible payment options. Oil& gas barter transaction is available for your choice.

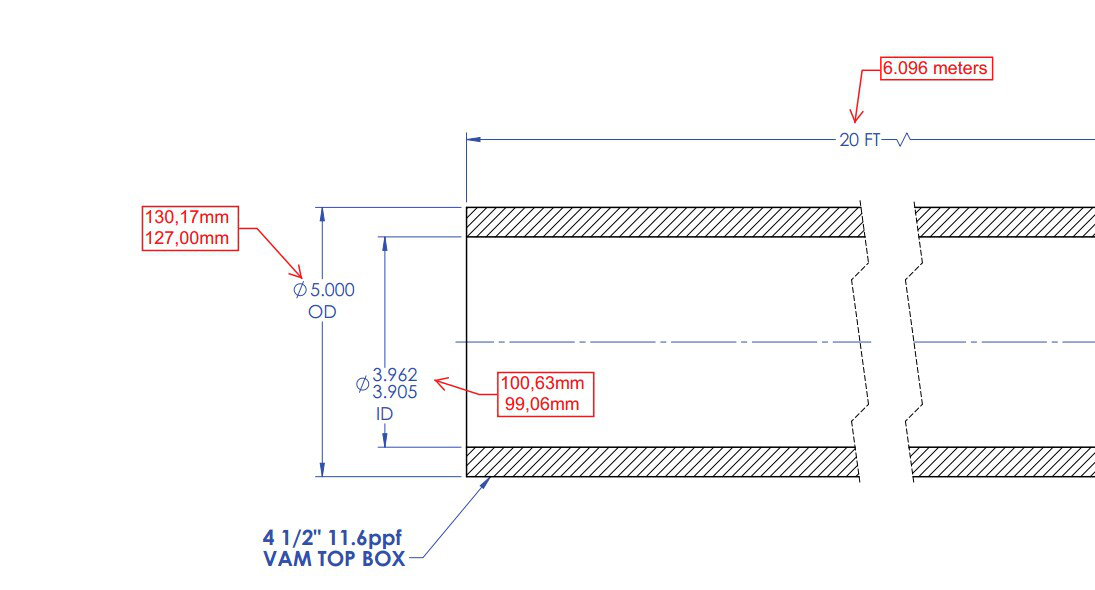

Below you may find a case of L80-13CR JPP offered to Canadian customer.

Material required:

Size: 5.000”-5.125”O.D.*3.905”-3.162”I.D.

Surface Finish: 125μinch

Material: 13CR-80K

Spec: API 5CT

Pipe End: Plain End – Ready for VAM Threading

Pipe Length: 20FT

Procedure:

1 : Technical Analysis ( acc. to drawing provided)

2:Pipe Rolling ( Seamless Raw Material: prevention of iron contamination)

3:Straightening& Boring from Inner Side

4:Drifting

5:Truning & Roll extrusion/ Honing(Inner Side)

6:Cut Length(Fixed Length)

7:Polishing the Outside Surface

8:Through-hole、Anti-rusting Oil Performance on the In & Outside Surface.

9:Package

10:Shipment

JPP Quality Control during the 10 Procedures:

1. Technical Analysis ( acc. to drawing provided)

2. Pipe Rolling ( Seamless Raw Material: prevention of iron contamination)silicon carbide used instead of normal iron sand to prevent iron contamination

Rubber wrapped on outside surface of equipment

3. Straightening & Boring from Inner Side

4. A Drift Bar Especially Made acc. to Customer Requirement:

98.42mm Dia * 1.066 m Long

5. Cylindrical Turning & Roll extrusion/ Honing(Inner Side)

7. Polishing the Outside Surface

9. Package

10. Shipment

CN

CN RU

RU